How Screen Printing Custom T-shirts Abilene can Save You Time, Stress, and Money.

Our Screen Printing Custom T-shirts Abilene Ideas

Table of ContentsNot known Details About Screen Printing Custom T-shirts Abilene Fascination About Screen Printing Custom T-shirts AbileneThe 7-Second Trick For Screen Printing Custom T-shirts AbileneFacts About Screen Printing Custom T-shirts Abilene RevealedSome Ideas on Screen Printing Custom T-shirts Abilene You Need To KnowThe Best Guide To Screen Printing Custom T-shirts Abilene

No mixing required, remedies exceptionally promptly, costly, appropriate for in-depth job. Combination of Diazo and SBQ, requires mixing, total remedy time is much less than Diazo, price is reduced than SBQ. The clear acetate movie is put on the emulsion-coated mesh screen meticulously under a bright light which triggers the emulsion to set and develop.Subjecting the display for a details time will certainly harden the uncovered areas of the display, and the remaining unhardened solution, if any kind of, will certainly be rinsed away to leave a clear imprint on the display. The display is after that dried, and if there are any type of touch-ups needed, it will be done by the printer to make the imprint as near the original layout as feasible.

The product to be published is placed level on the printing board, and the screen in addition to the product in the wanted position, ready to be printed. In this step, the printed style will revive. The display is reduced to the printing board. The wanted colour ink is included to the top of the screen.

The ink presses through the open areas of the stencil and transfers on the underlying silk, subsequently printing the style on the product. The stencil will have offered its function when all the items are printed. An unique cleaning liquid is made use of to remove the emulsion to reuse the mesh for producing brand-new patterns.

How Screen Printing Custom T-shirts Abilene can Save You Time, Stress, and Money.

This is done so that the layout does not disappear. There are six various types of screen printing processes. Considering that different strategies will offer different results, it is very important to recognize the various kinds. One of the most usual display printing strategy is spot colour display printing. Spot colour display printing uses the ink's supply colour by printing it via the stencil of the mesh.

It is much easier to make use of as contrasted to other display printing techniques. It can be an excellent choice for printing on t-shirts, jackets, and hoodies, for instance. In halftone printing, single colours in gradients are published. The whole procedure utilizes a solitary colour of ink, and this colour obtains half-toned, leading to a various color when checked out from a distance.

In addition, it is a cost-efficient technique given that just one colour of ink is used. Grayscale printing is an excellent approach of publishing full-colour pictures as one colour grayscales or halftones.

Rumored Buzz on Screen Printing Custom T-shirts Abilene

Duotone printing makes use of the combination of 2 halftones for publishing the exact same picture with two colours. A black halftone is published with black ink, and then a 2nd halftone is published with colour ink.

It involves the four basic colours cyan, magenta, yellow and black. These 4 colours are integrated to create the required colour tones. It can be done by hand however ideally ought to be done instantly for best results. The substitute printing process combines the four-colour printing process with area colour printing. Because this technique is helpful for both lighter and darker tones, it is functional and preferred with people aiming to produce photorealistic print detail.

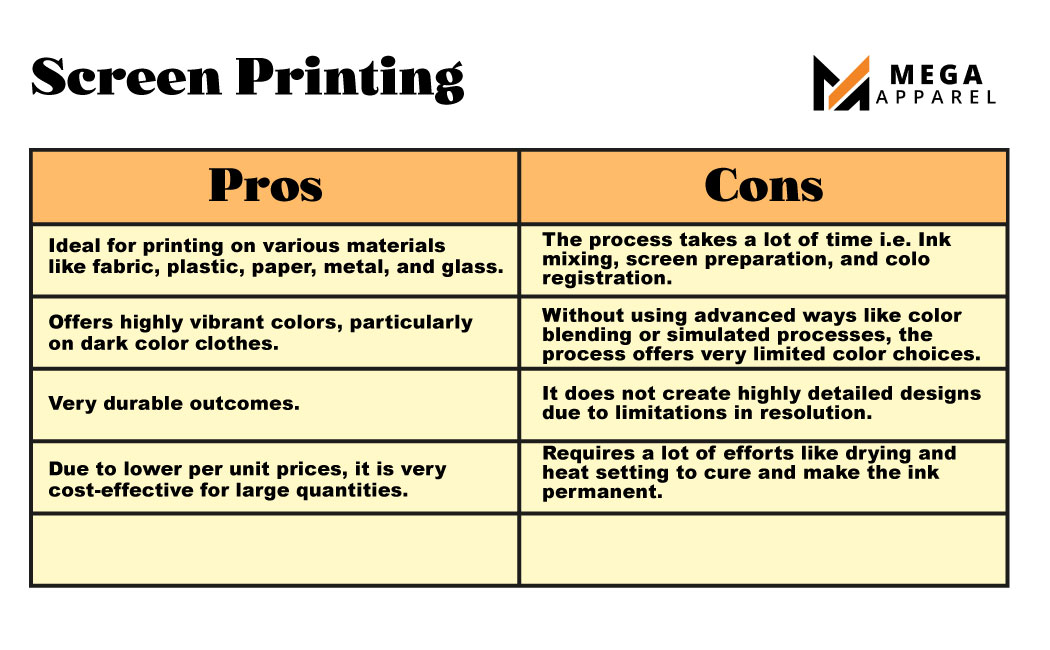

Some of these advantages include: One of the major advantages of display printing is its adaptability. Compared to other printing methods, screen printing can use a hefty ink insurance coverage, resulting in a resilient style.

The Definitive Guide for Screen Printing Custom T-shirts Abilene

Screen printing is one of the most effective and fast printing techniques when a display has actually been developed. The display printing process is rather uncomplicated, whether it is automated or done manually.

Custom display printing is a procedure that makes use of a mesh display to press ink in a fixed design onto the textile of your selection. Screen printing is prominent for custom-made tees, sweatshirts, coats, and much more. Custom-made display printed tees or various other screen-printed garments are the perfect way for services to increase their brand name presence.

Screen Printing Custom T-shirts Abilene for Beginners

The ink's longevity makes certain that prints endure repeated washing and wear, making it excellent for fabrics like t-shirts, hoodies, and tote. This technique works with a broad array of surface areas, including fabrics, plastics, glass, wood, and metals. Its flexibility enables companies and developers to apply layouts to items like garments, promotional items, signage, and product packaging.

Innovations like computer-to-screen (CTS) and direct-to-screen (DTS) innovations are reinventing the screen printing procedure. These methods remove the requirement for traditional movie positives by electronically transferring screen printing styles straight onto the display.

Some Known Questions About Screen Printing Custom T-shirts Abilene.

While rooted in custom, display printing has actually accepted technological advancements to fulfill modern-day needs. Its mix of craftsmanship and advancement guarantees it continues to be a leading selection for innovative and business printing projects. Display printing remains to be a trusted and versatile printing method, using vibrant colors and sturdy layouts that stand out on a variety of materials.

For garment style that needs a high level of vibrancy when publishing on dark premises, display printing is still the ideal option.

per product) are much quicker. Thus higher quantities can be mass created using display printing quicker and even more cost efficiently for larger orders. Display printing suits a large variety of products, including vinyl, material, inflexible plastic, foam board, metal, glass and several others. The printer can produce different items, such as banners, T-shirts, hats, posters and wallpapers utilizing the very same screens.